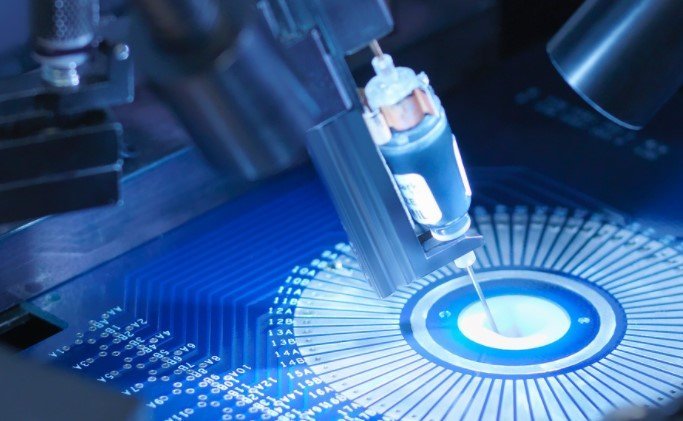

With today’s technology advancing so quickly, the electronics industry faces immense pressure to keep up. From smartphones to smart homes, consumer demand for complex and flawless devices is at an all-time high. This is where cognitive manufacturing comes in, using smart technologies like cognitive computing and the Industrial Internet of Things (IoT) to revolutionize how electronics are made. It helps companies build better products faster and more efficiently than ever before.

What Exactly is Cognitive Manufacturing?

Cognitive manufacturing is a modern approach that brings artificial intelligence into the factory. It uses a combination of advanced technologies to create a production system that can think, learn, and adapt on its own. Instead of relying only on human observation and old machines, this system collects and analyzes huge amounts of data from every step of the manufacturing process.

The main goal is to make the entire operation smarter. By identifying patterns and potential issues that a human might miss, cognitive manufacturing helps to streamline workflows, prevent errors, and make better decisions in real-time. It’s about turning a traditional factory into a smart, self-optimizing environment.

At its core, cognitive manufacturing uses cognitive computing, the industrial IoT, and advanced analytics to solve complex production problems. This powerful trio works together to understand the vast data points generated on the production line, from machine performance to supply chain logistics. This deep understanding allows for continuous improvement and innovation in how electronics are designed and built.

How it Transforms Electronics Production

The transformation from traditional to cognitive manufacturing is significant. In the past, producing complex electronics like smartphones involved a delicate and often inefficient balance between human labor and basic machinery. Identifying the root cause of a defect could take weeks of manual inspection and guesswork.

Cognitive manufacturing changes this by creating a fully connected system. Sensors placed on machines (the Industrial IoT) constantly stream data about their health and performance. This data is then analyzed by cognitive computing systems, which can predict when a machine needs maintenance before it breaks down. This predictive capability alone saves companies millions in downtime and repair costs.

It also improves the design and development process. By analyzing production data, engineers can see which product designs are difficult to manufacture or prone to errors. This feedback loop allows them to create better, more reliable products from the start.

| Feature | Traditional Manufacturing | Cognitive Manufacturing |

|---|---|---|

| Decision Making | Based on human experience and historical data. | Data-driven and automated in real-time. |

| Error Detection | Reactive; finds errors after they occur. | Proactive; predicts and prevents errors. |

| Efficiency | Limited by human and machine capabilities. | Continuously optimized for speed and quality. |

The Core Benefits for Electronics Companies

Adopting cognitive manufacturing brings several game-changing advantages to electronics companies, helping them stay competitive in a fast-paced market. These benefits go beyond just making things faster; they fundamentally improve the entire business operation.

The most immediate impact is on productivity and efficiency. Smart systems can identify bottlenecks and inefficiencies, allowing factories to produce more units in less time. This increased output directly translates to higher revenue and a stronger market position.

Another crucial benefit is the improvement in product quality and reliability. By catching potential defects early, cognitive systems ensure that fewer faulty products make it to the market. This not only saves money on recalls and repairs but also builds a stronger brand reputation for quality.

Other key advantages include:

- Increased Profitability: With fewer errors and greater efficiency, the cost per unit goes down, leading to higher profit margins for the company.

- Better Resource Management: Smart analytics help optimize the use of raw materials and energy, reducing waste and contributing to more sustainable manufacturing practices.

- Greater Agility: Cognitive systems allow factories to quickly adapt to changes in product design or consumer demand, a critical ability in the electronics sector.

Improving the Workforce with Smart Technology

A common misconception is that smart technology and automation are meant to replace human workers. In cognitive manufacturing, however, the goal is to empower the workforce, not eliminate it. It helps bridge the gap between human skills and the complex demands of modern production.

The system takes over repetitive, tedious, and physically demanding tasks. This frees up employees to focus on more creative and strategic roles, such as process improvement, quality control oversight, and complex problem-solving. It lessens the amount of manual labor expected from the workforce without cutting down on production outcomes.

By unearthing the most efficient processes, cognitive computing helps create a better working environment for employees. It provides them with the data and tools they need to perform their jobs more effectively and safely. This man-machine collaboration is key to achieving optimal results for everyone involved, from the factory floor to the end customer.

Why an Investment in Cognitive Manufacturing Pays Off

In a nutshell, cognitive manufacturing is no longer a luxury but a necessity for the electronics industry. The sector is fundamentally dependent on technology and data, and cognitive systems provide the intelligence needed to manage that data effectively. It is a great investment for any company looking to achieve efficient and stellar results.

From refining product designs to creating entirely new devices, the insights derived from cognitive computing are invaluable. It allows companies to solve manufacturing problems that are simply impossible to figure out with the human eye alone. By embracing this technology, electronics manufacturers can catapult their production to new heights and secure their place in the future of technology.

Frequently Asked Questions

What is cognitive manufacturing in simple terms?

Cognitive manufacturing is the use of smart technologies like artificial intelligence (AI), the Internet of Things (IoT), and data analytics to make manufacturing processes smarter, more efficient, and self-optimizing. It helps factories learn from data to prevent errors and improve production.

How does cognitive manufacturing improve product quality?

It improves quality by constantly monitoring the production line for tiny variations or potential defects. By using predictive analytics, the system can flag potential issues before they lead to a faulty product, ensuring a much higher standard of reliability and fewer errors.

Is cognitive manufacturing replacing human workers?

No, the goal is not to replace humans but to enhance their capabilities. It automates repetitive and difficult tasks, allowing employees to focus on more complex, value-added activities like innovation and problem-solving. It creates a collaborative environment between people and machines.

What are the main technologies behind cognitive manufacturing?

The three core technologies are cognitive computing (AI systems that mimic human thought), the Industrial Internet of Things (a network of connected sensors and machines), and advanced analytics (the process of examining large data sets to find patterns and insights).

Why is this so important for the electronics industry specifically?

The electronics industry deals with highly complex products, rapid innovation cycles, and massive amounts of data. Cognitive manufacturing is essential for managing this complexity, improving the design of intricate chips and software, and producing high-quality devices efficiently.

Leave a Comment