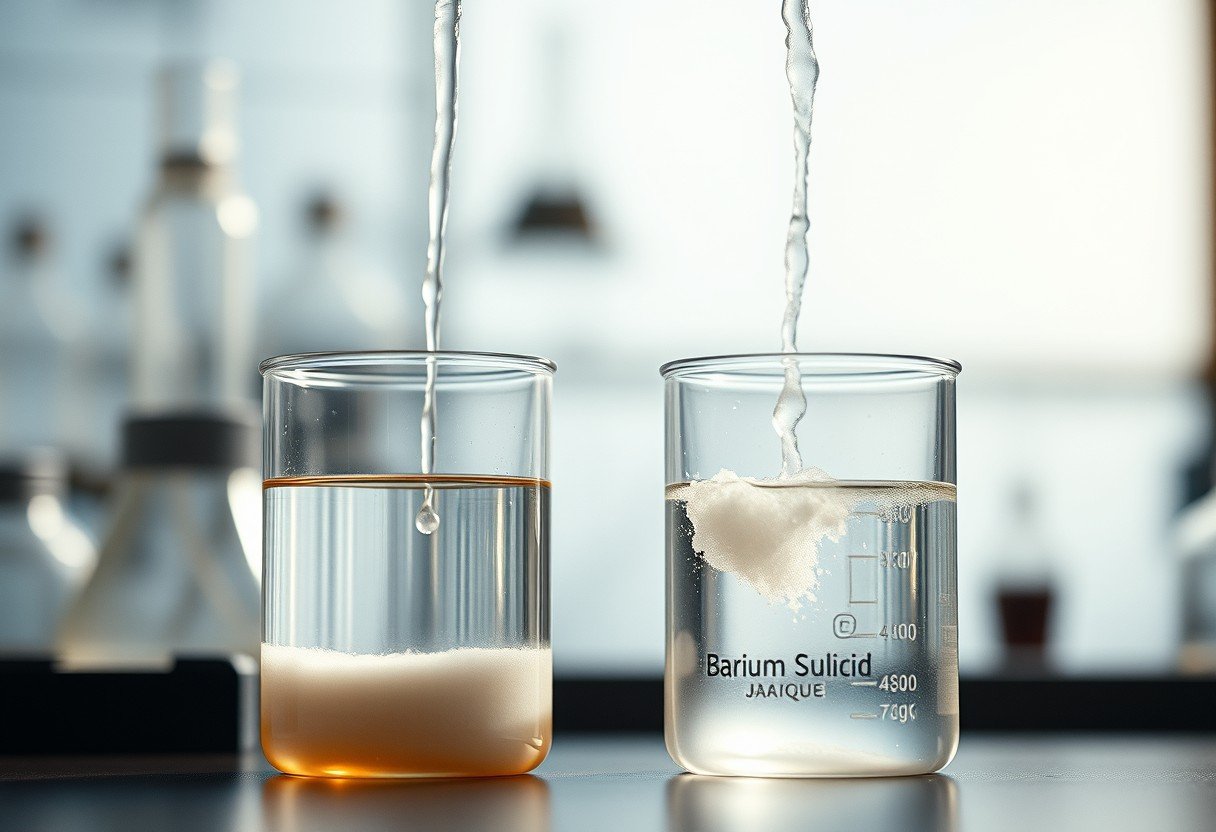

When you mix aqueous solutions of barium sulfide and sulfuric acid, a dynamic chemical reaction unfolds. This process involves a double displacement reaction, creating a solid precipitate and a distinct-smelling gas. Understanding what happens is key for anyone in a lab or industrial setting, as it demonstrates core chemistry principles and highlights important safety considerations you need to be aware of.

A Closer Look at the Chemicals Involved

To understand the reaction, you first need to know about the two substances you are mixing. Barium sulfide and sulfuric acid each have unique properties that dictate how they will interact when combined.

Barium sulfide (BaS) is an ionic compound that dissolves in water. When it dissolves, it releases barium ions (Ba²⁺) and sulfide ions (S²⁻) into the solution. It has a strong alkaline nature, making it a base in this chemical interaction.

Sulfuric acid (H₂SO₄), on the other hand, is a very strong acid. It is known for being highly corrosive and reactive. In water, it completely separates into hydrogen ions (H⁺) and sulfate ions (SO₄²⁻). This high concentration of ions makes the solution very reactive.

Understanding the Double Displacement Reaction

The reaction that occurs is a classic example of a double displacement, or double replacement, reaction. Think of it like the chemicals swapping partners. The positive ion from one compound pairs up with the negative ion from the other compound, and vice versa.

In this specific case, the barium ions (Ba²⁺) from the barium sulfide are attracted to the sulfate ions (SO₄²⁻) from the sulfuric acid. At the same time, the hydrogen ions (H⁺) from the sulfuric acid combine with the sulfide ions (S²⁻) from the barium sulfide.

This exchange is driven by the formation of stable new products, which is what makes the reaction proceed. The creation of an insoluble solid and a gas are powerful driving forces in chemistry.

What Products are Formed in This Reaction?

Mixing these two solutions yields two primary products: a solid precipitate and a gas. The formation of these new substances is the main outcome of the chemical change.

The main product you will see is barium sulfate (BaSO₄). This compound is a white solid that is not soluble in water, meaning it will not stay dissolved. Because of its low solubility, it forms a precipitate that settles at the bottom of the container.

The other product is hydrogen sulfide (H₂S), a gas. This gas is created when the hydrogen and sulfide ions combine. Depending on the concentration of the reactants, you may see bubbles forming as the gas is released from the solution.

| Product Name | Chemical Formula | State | Key Property |

|---|---|---|---|

| Barium Sulfate | BaSO₄ | Solid (s) | White, insoluble precipitate |

| Hydrogen Sulfide | H₂S | Gas (g) | Has a “rotten egg” smell |

Observing the Chemical Changes: What to Look For

When you perform this reaction, there are clear signs that a chemical change is happening. These observations are a direct result of the products being formed.

The most immediate and obvious sign is the formation of the white precipitate. As soon as the solutions mix, you will see the clear liquid turn cloudy and a solid substance begin to form and settle. This is the barium sulfate separating from the solution.

You might also notice bubbling or fizzing, which is the hydrogen sulfide gas escaping. Alongside the bubbles, you may detect a very unpleasant smell similar to rotten eggs. This odor is a tell-tale sign of hydrogen sulfide gas and a warning that you should be in a well-ventilated area.

Crucial Safety Precautions You Must Follow

Handling the chemicals involved in this reaction requires strict safety measures. Both the reactants and the products can be hazardous if not managed correctly.

Sulfuric acid is highly corrosive and can cause severe burns, while barium compounds can be toxic if ingested or inhaled. The most significant immediate danger, however, is the hydrogen sulfide gas produced. Hydrogen sulfide is toxic and can cause serious respiratory problems, even at low concentrations.

To ensure safety, you must always follow proper lab procedures:

- Wear appropriate personal protective equipment (PPE), including chemical-resistant gloves, safety goggles, and a lab coat.

- Perform the reaction in a well-ventilated area, preferably inside a fume hood, to prevent the inhalation of hydrogen sulfide gas.

- Know the location of emergency equipment like eyewash stations and safety showers.

- Handle waste properly. The byproducts must be neutralized and disposed of according to hazardous waste guidelines.

Never work alone when dealing with these substances, and always add acid to water slowly, not the other way around, to control any heat generated.

Real-World Applications and Implications

This reaction is not just a laboratory curiosity; it has important uses in various industries. The primary product, barium sulfate, is a valuable commercial compound.

Because of its high density, brightness, and chemical inertness, barium sulfate is widely used. It serves as a filler in plastics and rubber, a pigment in paints, and a weighting agent in drilling fluids for the oil and gas industry to prevent blowouts.

However, the reaction also has environmental implications. The potential release of toxic hydrogen sulfide gas and the contamination of water with barium ions pose risks to ecosystems and human health. Proper waste management is essential to balance the industrial utility of this reaction with environmental protection.

Frequently Asked Questions

What kind of chemical reaction occurs when you mix barium sulfide and sulfuric acid?

A double displacement reaction occurs. The positive and negative ions from the two reactants switch partners to form two new compounds: solid barium sulfate and hydrogen sulfide gas.

Is the precipitate formed during this reaction soluble in water?

No, the barium sulfate (BaSO₄) that forms is insoluble in water. This lack of solubility is why it appears as a solid white precipitate that settles out of the solution.

Why does this reaction have a bad smell?

The characteristic “rotten egg” smell comes from the production of hydrogen sulfide (H₂S) gas. This gas is formed when hydrogen ions from the acid react with sulfide ions from the barium sulfide.

What are the main safety hazards of this reaction?

The main hazards are the corrosive nature of sulfuric acid and the toxicity of both barium sulfide and the hydrogen sulfide gas produced. Inhaling hydrogen sulfide is particularly dangerous and requires proper ventilation.

Where is barium sulfate used in industry?

Barium sulfate is used in many industries. It is a key ingredient in paints, a filler for plastics, and a weighting agent for drilling fluids in oil and gas exploration due to its high density.

Leave a Comment